Introduction

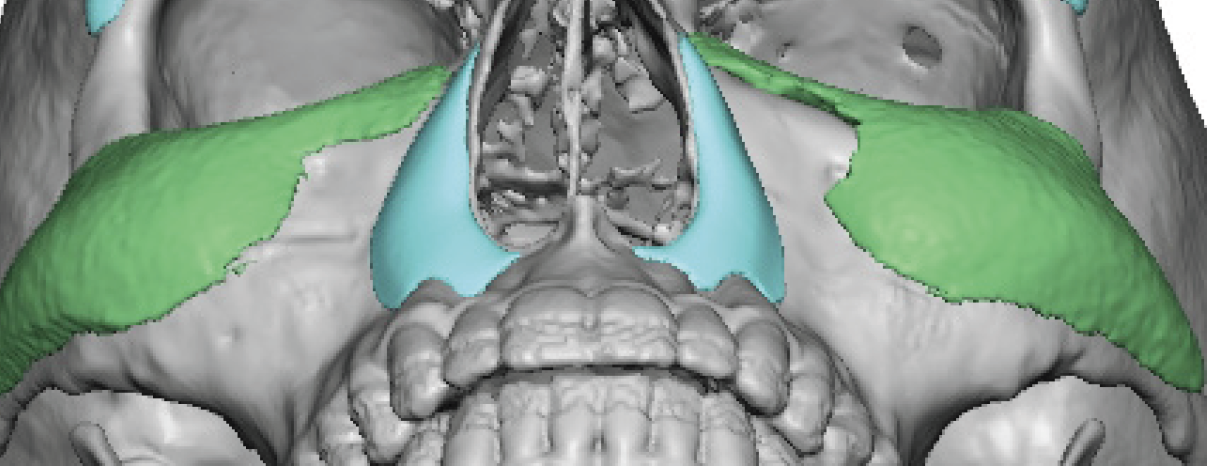

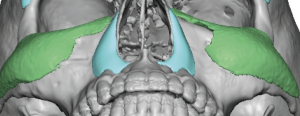

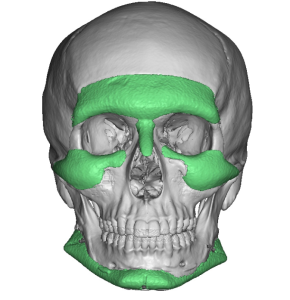

Paranasal implants are a well-established method of facial enhancement designed to augment the midface region—specifically the area around the sides of the nose (the paranasal or pyriform aperture region). This portion of the midface may appear flat or deficient due to individual skeletal development, aging, or an aesthetic desire for greater central midface projection.

The primary goals of paranasal augmentation are to:

-

Correct midface deficiency or flatness around the nasal base

-

Enhance the nasolabial angle and soften deep nasolabial folds

-

Complement other facial reshaping procedures to achieve balanced facial proportions

Ideal candidates for paranasal implants typically exhibit midface recession or hollowing, require improved nasal base support for better facial definition, or seek the procedure as an adjunct to rhinoplasty or other structural enhancements.

Standard paranasal implants have been fabricated from materials such as solid silicone, Medpor (porous polyethylene), and ePTFE (Gore-Tex), each offering distinct advantages and limitations. Regardless of material, the surgical technique remains similar—a small intraoral incision provides access for implant placement over the maxillary bone along the pyriform aperture.

As with all facial implants, a key consideration is whether to use a standard, off-the-shelf design or a custom-made implant.

Case Study

Discussion

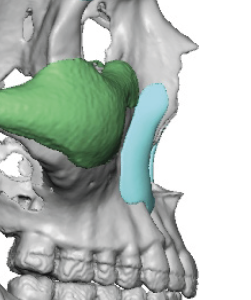

Custom 3D-printed implants offer superior anatomical precision and the flexibility to replicate complex bony contours, making them particularly valuable in correcting facial asymmetries. These advantages come with certain trade-offs—higher production costs and a lead time of several months.

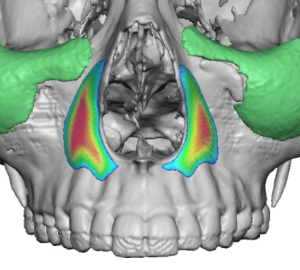

When designing custom paranasal (pyriform aperture) implants, key variables include:

-

Material composition – silicone, Medpor, or PEEK, with differences primarily in handling rather than biological response

-

Shape and footprint – typically crescent or half-moon–shaped paired designs, often extending laterally into the canine fossa for a smooth bony transition without a palpable edge

-

Projection (thickness) – most patients require approximately 5 mm of projection for noticeable improvement, though some may prefer less

-

Fixation method – secure pocket design may eliminate the need for fixation, but when desired, a single small self-tapping screw provides reliable stabilization

Key Points

-

Paranasal implants are commonly performed as part of comprehensive midface augmentation, often alongside cheek or infraorbital-malar implants.

-

Custom paranasal implants allow for precise control of shape and thickness, ensuring a tailored fit and predictable aesthetic result.

-

Due to their accurate contouring, custom implants can be placed through very small intraoral incisions.

Barry Eppley, MD, DMD

World-Renowned Plastic Surgeon