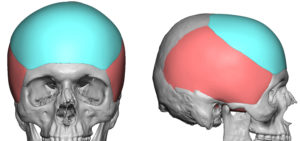

One of most common forms of forehead reshaping surgery is augmentation of the brow ridges and frontal bone. Many more women than men historically undergo forehead augmentation surgery, most likely because of hairline and hair density issues. But some men still have the procedure as they value the improvement of their frontal skull/forehead shape as more important than the risk of an adverse scalp scar. Most commonly these men have a severe sloping inclination to their forehead in profile, an inclination that exceeds the more aesthetically acceptable inclination of 10 to 15 degrees and they may also lack significant brow ridge prominences.

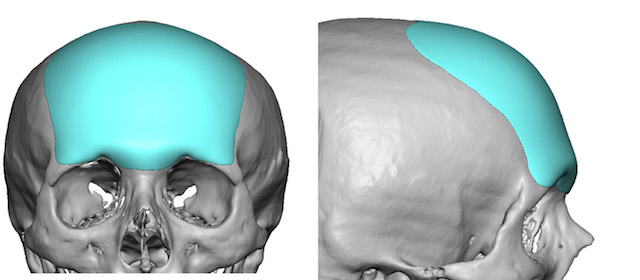

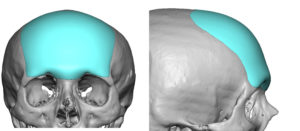

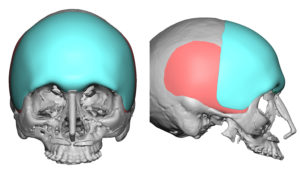

Regardless of the bone cement material used, it needs to be shaped to create the desired forehead shape. Besides the vertical inclination and the creation of a visible brow ridge if needed, the often overlooked part of forehead augmentation is its merging up to or across the anterior temporal line. A patient has to appreciate that you can not extend the bone cement material beyond the anterior temporal line which is the end of the width of the frontal bone. This is much more narrow that most people realize. Bone cements become unstable when placed onto the temporal fascia, particularly hydroxyapatite cements.

While traditionally a full open coronal incision is needed for optimal shaping of the material, this remains only true for the hydroxyapatite cements. If the forehead augmentation does not include the brow bones, it can done using PMMA through a far more limited scalp incision by an ‘injectable molding technique’. The working characteristics allow a subperiosteal tissue pocket to be created through which the PMMA material can be introduced and externally molded until set. There is a higher risk of potential material irregularities with this blinded technique and the user should have a lot of experience working with PMMA before attempting it. Any irregularities or asymmetries of the material is going to require a more extended scalp incision to adequately solve.

The use of custom implants for forehead augmentation has major implications in surgical placement and a resultant far smaller scalp scar needed. While several material options exist from which the implant can be made, solid silicone is the most economical and versatile material.

Dr. Barry Eppley

Indianapolis, Indiana