Introduction

Custom facial implants can be fabricated from a variety of materials, each with distinct advantages and disadvantages. One such material is PEEK (polyetheretherketone), a high-performance thermoplastic polymer from the polyaryletherketone (PAEK) family. Medical-grade variants of PEEK meet strict biocompatibility and sterilization standards, making them suitable for cranio-maxillofacial applications. PEEK implants can be machined or 3D printed to precisely match an individual’s anatomy.

Advantages of PEEK for Custom Facial Implants

-

Mechanical strength comparable to bone: PEEK exhibits strength and stiffness similar to natural bone.

-

Radiolucency: The material does not interfere with radiographic imaging.

-

Custom design capability: It can be precisely shaped to patient-specific contours.

-

Lightweight and dimensionally stable.

-

Biocompatible: Well tolerated by surrounding tissues.

Disadvantages of PEEK for Custom Facial Implants

-

Rigidity: PEEK’s stiffness makes intraoperative or postoperative modification difficult.

-

Radiolucency limitation: Although radiolucency aids imaging clarity, it also prevents visualization of the implant on CT scans, complicating postoperative assessments and potential revision planning.

-

Revision challenges: Revisions or replacements of facial implants—custom or otherwise—are not uncommon. In my experience, up to one-third of patients request modifications or replacements, most often for aesthetic reasons.

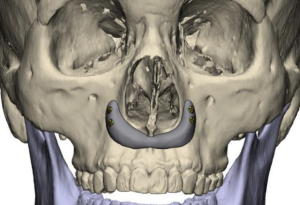

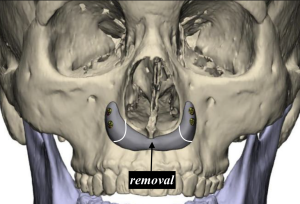

Case Study

Discussion

From a biocompatibility perspective, PEEK remains a safe and effective option for custom facial implants. Because there are no standard implant shapes for such anatomical sites, PEEK’s ability to be tailored to each patient’s unique needs is advantageous. However, its milling-based manufacturing process limits the ability to achieve extremely refined edges, which may be more noticeable in areas with thin overlying soft tissue.

The major drawback of PEEK implants is their limited potential for secondary modification. Although PEEK’s rigidity makes it an ideal bone overlay material, it also prevents substantial reshaping after initial implantation. Minor adjustments can be made with difficulty, but most shape changes require removal and fabrication of a new custom implant.

Every implant material involves trade-offs, and no custom design can fully overcome these inherent material characteristics. In the case of PEEK, radiographic invisibility and difficulty with secondary reshaping are important considerations, especially since aesthetic revisions are relatively common.

Dr. Barry Eppley

World-Renowed Plastic Surgeon

Key Points

-

Secondary modification of custom PEEK facial implants requires high-speed drilling with burrs and offers only limited potential for contour changes.

-

In most cases, implant removal and external modification provide better control and precision than in-situ adjustments.

-

For minor refinements in areas with thicker soft tissue coverage and good access, limited in-situ modifications may be feasible.

Barry Eppley, MD, DMD

World-Renowned Plastic Surgeon