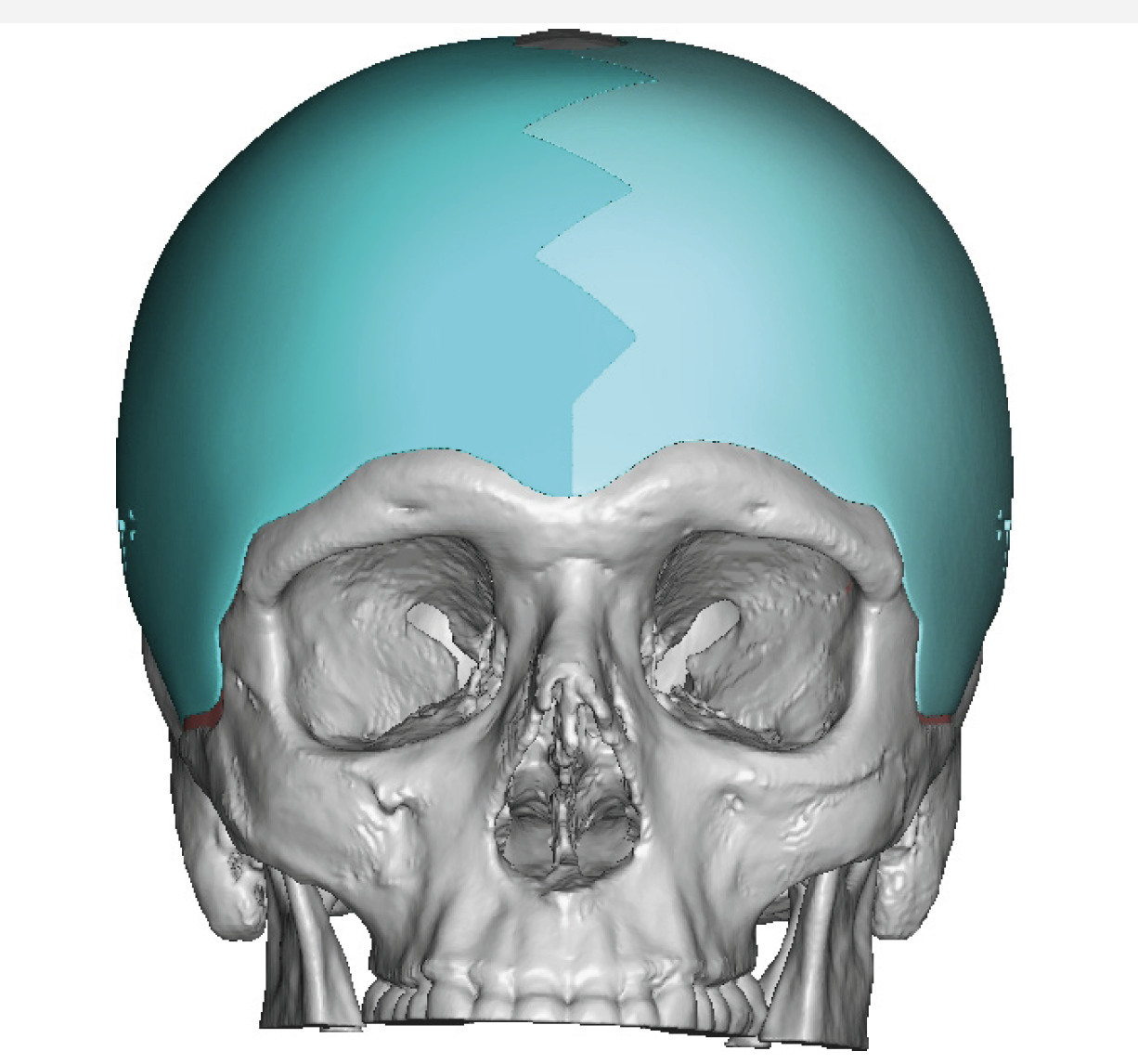

Background: Aesthetic augmentation of the skull can now be performed in an almost limitless fashion. This has become possible due to the readily accessible 3D CT skull scanning and the use of computer designing on onlay skull implants. In some ways what had been available for facial bone augmentation has now been extended to the skull. While there are a few standard implants that are currently available for local skull augmentations (temporal and forehead implants) theist majority of aesthetic skull augmentation needs requires custom implant designing given their lager surface areas of coverage.

With custom implant designing almost any form of skull augmentation can be done constrained only by the ability of the scalp’s stretch to accommodate the implant volume placed underneath it. But another challenge is created…how to place such skull inplants without undue scarring. While the bicoronal scalp incision provides unlimited visual access to all areas of the skull and is routinely used in reconstructive craniofacaial surgery, it has a much more limited role in aesthetic craniofacial procedures. Most men in particular are understandably not accepting of that long often visible scar tradeoff.

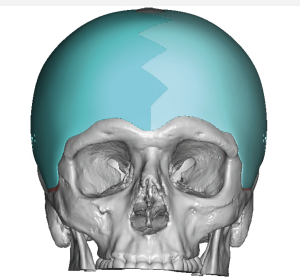

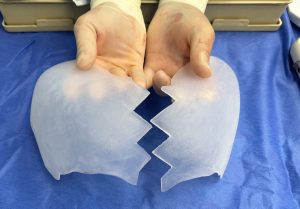

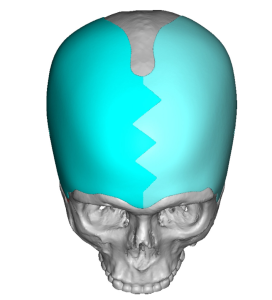

One of the basic principles of aesthetic craniofacial/skull augmentation surgery is limited scarring. How then can a large surface area coverage skull implant be placed? Much like the proverbial ship in the bottle the implant must be designed in pieces, inserted in separate sections and then reassembled once inside. How the implant design should be sectioned is determined by the location of the placement incisions with thought into how it will be put together once inside the tissue pockets. The following case is a prime example of this large skull implant design concept.

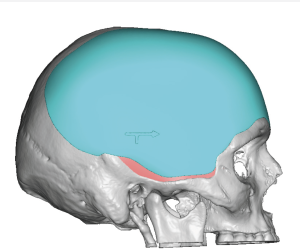

This is a large surface area coverage skull implant which one would think that it could only be placed though a coronal scalp incision. But as seen in this case example that incisional approach can be avoided through a two-piece implant design. It also works because the implant is flexible permitting its shape to be changed for introduction through small remote incisions. It also works in head widening implants, contrary to the perception of some, that the implant needs to placed on top of the temporal fascia and not beneath it or the muscle. The continuous plane of placement goes from the frontal bone over onto the fascia is what makes one smooth augmented contour change.

Usually getting the implant together along the midline forehead split is not a problem. But in this overall thin implant (maximum thickness of 6mms) it just would not slide completely together. Coverage of the open implant split was essential and a 1mm ePTFE implant works well to do so with not visible edging.

Key Points:

1) Widening of the side of the head and forehead augmentation can be done by a combined wrap around skull implant covering more than two thirds of he circumference of the skull.

2) Such a large skull implant must be designed into at least two or more pieces for placement through limited incisions.

3) Placement of the two-piece skull implant design is introduced through postauricular incisions aided a small central frontal hairline incision for implant positioning.

Dr. Barry Eppley

World-Renowned Plastic Surgeon