Background: Jaw angle augmentation has become an increasingly popular area for facial augmentation. No longer is the chin the only lower facial area that can be enhanced by onlay bone implants. Jaw angle implants have been around for three decades when they were initially introduced in solid silicone form. Despite their existence and the development of other materials by which they could be made (Medpor, ePTFE) they never caught much traction in clinical use until more recently. Currently the widespread use of injectable fillers, in which any facial area can be temporarily augmented, and with the contemporary recognition of a more defined jawline for both men and women as being aesthetically attractive, jaw angle implants have become more commonly requested.

While numerous styles of standard jaw angle implants exist, a custom design approach to them works better for some patients. Unlike the chin the jaw angles are paired structures which often are not identical in shape. When you factor in that jaw angle implants are the most technically challenging of all facial implants to surgically place in a symmetrical fashion, the risks of postoperative jaw angle implant asymmetry are not rare. Some patients may also have the need for jaw angle augmentations that have extraordinary aesthetic requirements, particularly vertical lengthening in which standard implants can not achieve.

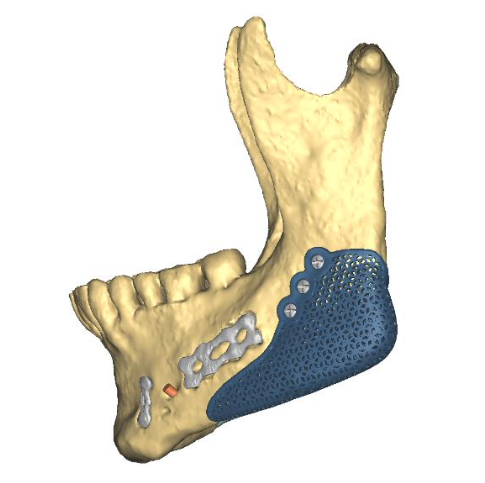

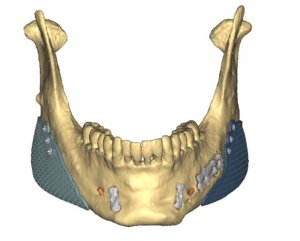

Custom jaw angle implants can be made from a variety of known materials using the patient’s 3D CT scan. Solid silicone, porous polyethylene (Medpor) and PEEK are the most commonly used, each with their own distinct advantages and disadvantages. The most rarely used material is titanium metal. Given its long standing history has a craniomaxillofacial implant material for traumatic and reconstructive surgeries as well as their biocompatibility with bone from dental implant expererience it is a bit surprising that it is so rarely used as an aesthetic only material. While much is known about titanium as a reconstructive material, very little is known as a facial implant material.

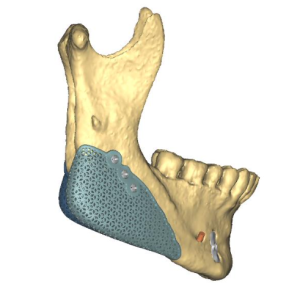

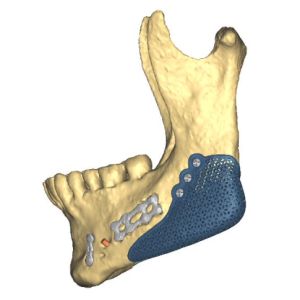

- While significant soft tissue adherence was expected, and there certainly was adhesions into the mesh construct of the implant, it was less aggressive soft tissue adherence than with Medpor. (meaning it elevated of the material a bit easier than Medpor)

- Bony overgrowth was seen over the top edge of the implant and into the material along the inferior border where it had contact with bone.

The implant was able to be dissected free of the enveloping soft tissues, the two fixation screws removed, bone removal by osteotomes and complete mobilization of the implant. It was moved down and rotated inward to be in complete vertical alignment with the bone and secured in its new position with two new screws.

While titanium would be the most costly all of custom jaw angle implant materials, it does have some unique advantages. It has clear biocompatibility with the bone and develops osseous integration where it contacts the bone’s surface. It de Pelops soft tissue adherence which is enhanced by the mesh construct of the implant. It certainly is a rigid material which should lessen the risk of implant malposition in more significant vertical elongations where the amount of material that is off the bone is greater than what is on it. Besides the cost its disadvantages, like all rigid materials, is that it requires larger intraoral incisions to place and is harder to secondarily adjust or remove if needed. But as shown in this case such adjustments can be secondarily done.

Case Highlights:

1) Jaw angle implants can be made custom made from a variety of materials including silicone, Medpor, and PEEK as the most commonly used.

2) Custom titanium jaw angles is the most rarely used material from which they are fabricated and it has own distinct advantages.

3) Adjusting a malpositioned titanium jaw angle implant poses challenges but also provides insight into its biologic behavior as an aesthetic only augmentation material.

Dr. Barry Eppley

Indianapolis, Indiana