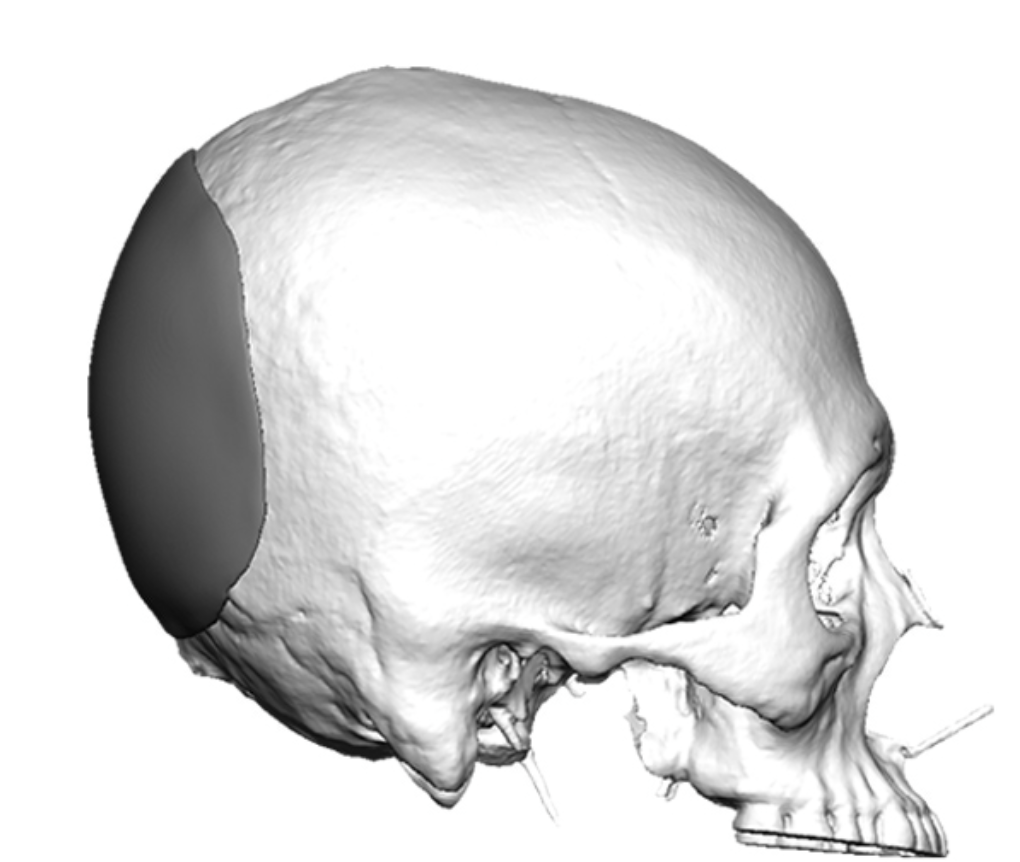

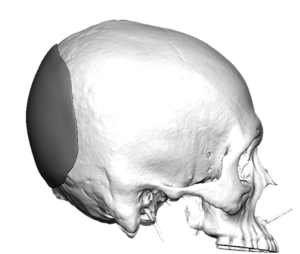

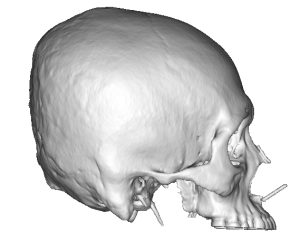

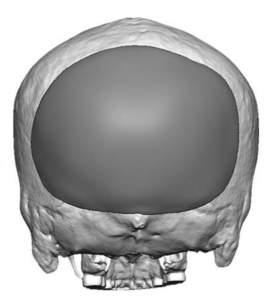

Background: Aesthetic skull augmentation can be done by a variety of materials which can be divided into rigid and semi-rigid physical properties. Silicone is the most commonly used of the materials as its semi-rigid forms allows for introduction through smaller incisions, can be designed in almost any shape and thickness and has feathered edges. These features make it far superior to use over any of the rigid implant materials.

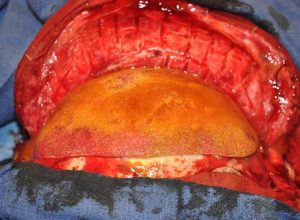

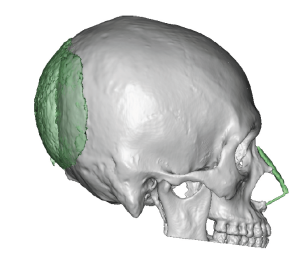

But occasionally I will get a patient who wants to use a rigid implant material which can be done IF they can accept a long scalp scar to place it. One of these rigid implant materials is HTR, an acronym for Hard Tissue Replacement. It has a long history of use as a cranial implant, an inlay used as a skull bone replacement. It is a material composed of PMMA-pHEMA beads that have been sintered together to create a rigid but porous implant. But besides its porosity its most interesting property feature is hydrophility which is created by the pHEMA component. This pulls cellular and tissue elements into the implant material causing tissue ingrowth.

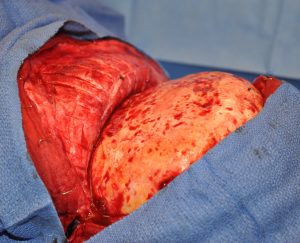

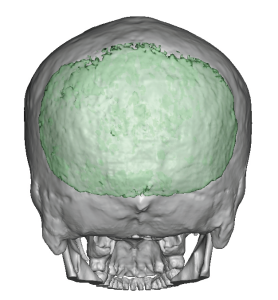

But despite its positive biologic properties it has some negative implants characteristics. Besides its rigidity it can not be manufactured with a feathered edge. It was never meant as an onlay augmentation material. And what it is well known in only skull implants is that the edges must be very feathered to not be seen in the shaved/bald head patient or have a very palpable edge in the patient with hair. Overcoming this material features requires intraoperative method to manage this edge transition problem.

HTR polymer has very favorable biologic properties as an onlay skull augmentation material. But its physical properties require a long scalp incision for placement and intraoperative management of its non-feathered edges.

Key Points:

1) HTR is an uncommon material for aesthetic skull augmentation even though it offers very favorable tissue ingrowth properties.

2) An HTR skull implant requires wide open scalp access for placement due to its rigid structure.

3) An HTR cranial implant as an onlay requires the additional application of bone cement to create a smooth transition onto the surrounding skull surface.

Dr. Barry Eppley

World-Renowned Plastic Surgeon