Background: Cranial or skull reconstruction has been done for over half a century with a wide variety of different materials. Whether its is done using the patient’s own bone, bone substitutes or synthetic materials, successful skull reconstruction can be accomplished with all of them if skillfully done. But because of the availability limitations of using the patient’s own bone and the structural limitations of bone substitute materials, the use of synthetic materials remains the mainstay of major skull reconstruction today.

The use of polymethylmethacrylate (PMMA) bone cement, intraoperatively mixed and applied, has been the mainstay of skull reconstructions for decades. It is relatively inexpensive, highly resistant to fracture, and can be loaded with antibiotics for postoperative release. But it does require skill in shaping it and it does not permit tissues to adhere/stick to it.

While still effective PMMA has been replaced over the past two decades by computer design technology and different types of synthetic materials. The standard of computer designed skull reconstruction has been HTR-PMI. This is a porous PMMA-based material that is formed by combining HTR beads (which are coated in calcium phosphate) into a solid composite based on the patient’s 3D CT scan of the defect. Due to its porosity and hydrophilic material quality, it has functioned very well as an implant reconstruction method for large skull defects. But it is not perfect as its edges must be thicker to prevent material fracture and it is actually made by hand from a negative impression of the patient’s skull model.

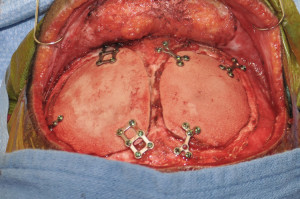

Custom designed (3D printed) skull implants made from a PEKK (PolyEtherKetoneKetone) material has become the new premier standard for large skull defect reconstruction. It has its origins from Polyether ether ketone (PEEK) which is a colorless organic thermoplastic polymer used in numerous engineering applications due to its robustness and resistance to wear. PEKK has very similar properties to PEEK but it has some superior properties including superior wear resistance, improved compressive strength and a lower water absorption capability.

Highlights:

- Custom designed 3D printed skull implants made from PEKK material offers a precision fit skull reconstruction method.

- Being able to be made thin with stronger mechanical properties is a significant advantage in a skull reconstructive material.

- PEKK skull implants require a 3D CT scan from which they are made.

Dr. Barry Eppley

Indianapolis, Indiana