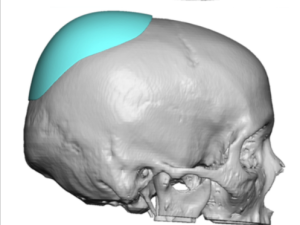

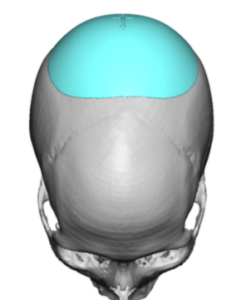

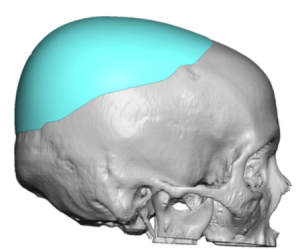

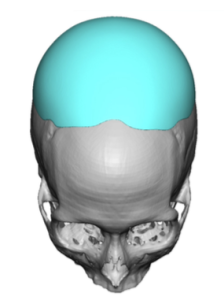

Aesthetic augmentation of the skull can be done on any of its five surfaces using a custom implant approach. Based on a 3D skull CT scan virtually any implant can be designed within the limits of how much the scalp can stretch to accommodate it. While the design possibilities are considerable there are no established guidelines to do so based on the relative short period of time the technology has been available for patient use. There is no transferable knowledge from 3D reconstructive skull implants as designing an implant to fill a cranial defect is not remotely the same as how to aesthetically enhance an intact skull surface.

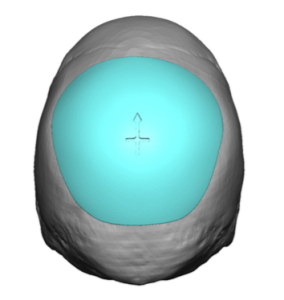

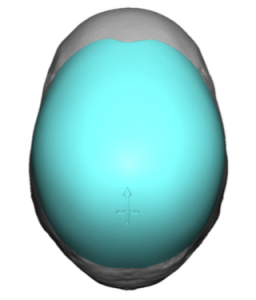

Having done many aesthetic skull implants there are some basic design considerations that are important for a pleasing and natural looking result. The best way to lilustrate these concepts is to look at custom skull implant designs that didn’t work out well that needed to be replaced. (patients which came to me with skull implants made from other surgeons seeking replacements)

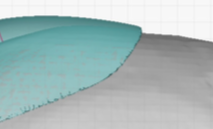

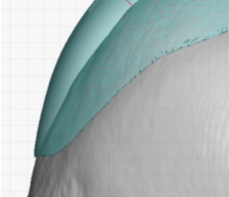

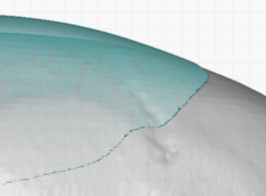

One of the over riding principles of custom skull implant design is that they must cover a much broader surface of the skull that one would initially think. The skull is essentially composed of convex surfaces of which each side blends into at least two or three of the other surfaces. In other words the skull shape is very connected and the base diameter of the implant must reflect this understanding of how the skull is shaped.

Dr. Barry Eppley

Indianapolis, Indiana