Chin implants are the most historic of all facial implants. As a result they have been through the greatest number of design changes and resultant size availabilities. Initial introduced a button shape the biggest design advancement came in the 1990s with the introduction of extended anatomic designs. This was a logical extension of the implant’s shape to blend in better to the surrounding bone and more effectively augment the chin bone in its entirety.

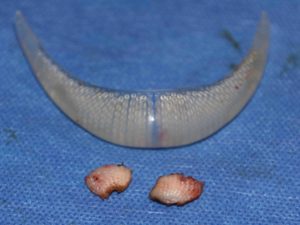

A more recent design change, and one that has been applied to cheek implants as well, is that of a textured inner surface. This mesh-like or pebbled surface is known as a Conform implant style. The concept basis for its use is that it provides greater implant flexibility for better and more complete implant adaptation to the bone. It is easy to see how such enhanced inner material flexibility has that effect. How much better that effect is over a smooth inner surface has not been evaluated.

The relevance of this thickened capsule layer underneath the implant is not known. Any corollary would have to come from textured implant surfaces in certain breast implants. It is well known that they produce a greater soft tissue response which leads to improved soft tissue adherence. This would explain the thicker capsular layer under Conform chin implants and presumably improved tissue adherence. Does this effect work equally well on the undersurface of the implant as opposed to its outer surface?

Dr. Barry Eppley

Indianapolis, Indiana