The Need and Benefits of Custom Facial Implant Designs

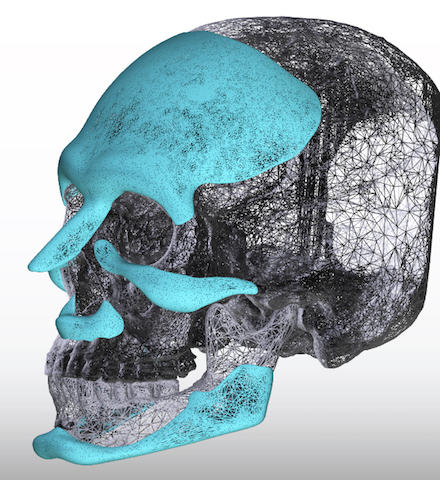

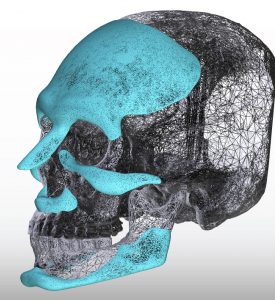

Besides changing facial beauty standards, the widespread use of injectable fillers and fat injections has made many patients aware of facial dimensional changes that they may find both pleasing and possible. The often transient effect of fillers and fat as well as the costs incurred in continuing those treatments over many years will have some patents seeking more permanent results through the use of implants. While implants are more invasive and are not without their own risks, their capabilities are tremendously expanded when they are custom designed for the patient’s specific anatomy and aesthetic needs.

While formerly known for use only in facial reconstructive facial surgery, custom facial implants now has a major impact on facial aesthetic surgery as well. The request for specific facial changes and inadequate outcomes from the use of off-the-shelf implants fuels the increasing demand for a custom-designed approach in aesthetic facial augmentation.

Custom facial implants can be made from a variety of different materials from silicone, Medpor, PEEK/PEK and titanium. I have made custom facial implants out of all of these materials. While I have no predilection for one material over another, it is important to appreciate that the material used will influence the design, how it is surgically placed as well as the cost of the surgery. The reason that solid silicone is used most frequently is because its flexibility and elastic deformation properties enables it to be placed through the smallest of incisions in the largest size or amount of bony surface area coverage possible. The more rigid the material the larger the placement incisions must become and/or the implant must be sectioned into multiple pieces for passage into the tissue pocket. As a result, the material’s composition/firmness has relevance as many custom-designed facial implants are large or have more complex shapes than off-the-shelf implants.

Custom Facial Implant Types

Dr. Barry Eppley

Indianapolis, Indiana