Unlike facial implants, the use of skull implants for aesthetic head reshaping has a very short history. While the use of facial implants dates back more than five decades in plastic surgery, skull implants have been done for just a few years. It has not been that skull implants are radically different or more complex to perform, it is just that there are no preformed skull implants currently available. With facial implants, there are dozens of different preformed options for the nose, cheek, orbital rim, chin and jaw angle areas.

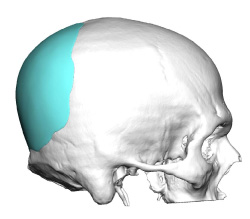

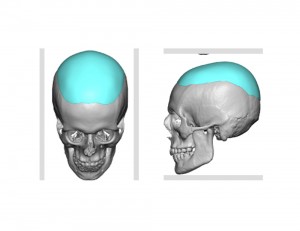

Custom Skull Implants Have Made Cosmetic Head Reshaping Possible. What really separates skull from facial implants from an implant standpoint is their size. Covering broad areas of the skull (e.g., back of the head) creates an implant that would be equivalent to over 20 or more chin implants. Getting such an implant to fit well is much more difficult than smaller facial implants and the margin of error is actually much less because of its size. The custom design and manufacturing of a skull implant makes their use much more predictable for any skull area.

A 3D CT Scan Is Needed To Make Custom Skull Implants. Whether it is done by an actual model or on the computer screen, only a high resolution 3D CT scan of the skull can be used. The scan has to be done using .1mm slices and not the standard 3mm or 1mm slices normally taken. A regular axial or coronal head CT scan will not work nor will an MRI. Today 3D CT scanning is widely available, quick and easy to do acan be done for a few hundred dollars.

The Computer Only Designs What The Surgeon Tells It To Do. While computers and their software have remarkable capabilities, they do not yet know how to create a specific look for any patient. In designing skull implants, it is important to remember that the computer has no innate knowledge of what the size and shape the implant needs to be for what the patient wants to be. The surgeon must work with the design engineer to create the amount of skull surface area (shape) and thicknesses of the implant to create what is believed to cause the ultimate aesthetic outcome. The computer design process will make sure the implants fit the bone perfectly, compensate for any skull asymmetries, have a smooth outer surface and will minimize any edge transitions.

Incisional Access Is Of Critical Importance In Custom Skull Implants. With large implants, the need to preserve hair follicles and to not create an additional aesthetic problem (scalp scar), the location and length of scalp incisions is critical. Despite most skull implant sizes they can be placed through relatively small incision in many cases because they are flexible. The implants can also be sectioned into two pieces and ‘reassembled’ once inserted if need be.

Dr. Barry Eppley

Indianapolis, Indiana