Background: The historic approach to aesthetic skull augmentations was with the use of bone cements. While still available today they have largely been replaced by custom skull implants in my practice due to their preoperative designs, superior augmentation effects and the ability to have them placed through small scalp incisions.

The only exception to the smaller incision scalp placement concept was with the use of PMMA bone cements. Their putty like physical characteristics after mixing and resistance to the influence of fluids make its insertion through small scalp incisions possible in properly selected patients. Once introduced into the created subperiosteal pocket they can be externally shaped by external molding of the overlying scalp. This is a blind procedure in that the shape of the material as it is being molded before it is set can only be assessed through the thickness of the overlying scalp.

Such blind placement techniques of PMMA bone cements for skull augmentation are not perfect. It is not rare that what is thought to be perfectly smooth during placement will reveal after the swelling has subsided and the scalp has finally contracted down around the implant material that imperfections can be seen/felt. This is mot commonly seen at the material edges with either a step off oran inadequate contour extension.

Case Highlights:

1) Bone cement skull augmentations through limited scalp incisions have a risk of an edge deficiency and contour deficiency.

2) The correction of bone cement skull augmentation edge deficiency requires the addition of additional material to extend and smooth out the material contour.

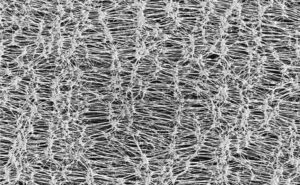

3) ePTFE sheeting offers one material that can be inserted and onlayed through small scalp incisions to correct bone cement irregularities.

Dr. Barry Eppley

Indianapolis, Indiana