Background: The flat back of the head is one of the common aesthetic skull deformities. It usually originates from either a genetic predisposition or a deformational effect of in utero or post birth head positioning. (occipital plagiocephaly) The flatness can be on just one side or both. (bilateral) When it occurs bilaterally there are aesthetic issues of skull disproportion that often bothers the person enough that they may great efforts at camouflaged by various hairstyles and hat wear.

Cosmetic correction of the flat back of the head is done using a variety of onlay implant materials. The contour of the bone is expanded through subperiosteal augmentation whose amount is controlled by the ability of the overlying scalp to expand.Those materials that are applied and shaped intraoperatively are several types of bone cements. (PMMA and hydroxyapatite cement) Preformed custom occipital implant materials include silicone, Medpor, HTR and PEEK. Of these custom shaped materials, only silicone is soft and flexible while the other polymers are quite rigid.

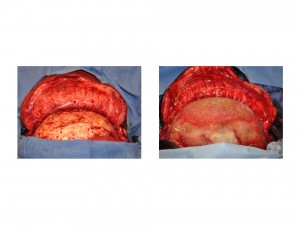

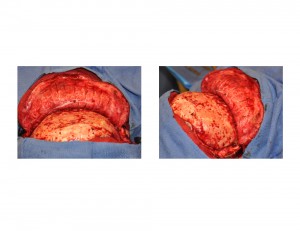

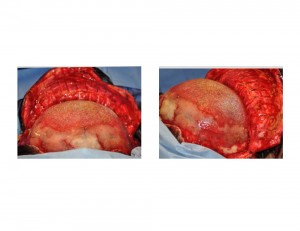

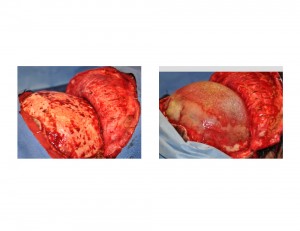

Case Study: This 38 year-old male had a very flat back of the head for which he had prior attempts at occipital augmentation. He had a prior occipital implant (material unknown) placed through a long coronal scalp incision which ultimately became infected and had to be removed. This left the back of his scalp scarred and more rigid than normal. He thoughtfully considered all the implant materials and chose HTR because of its potential to become vascularized throughout the material. A 3D CT scan was used to create an occipital implant design of 18mm thick at its central portion.

Rigid implant materials like HTR can be successfully used in aesthetic skull augmentations. But the material characteristics makes for the need to use a long scalp incision for placement and some experience on knowing how to properly secure it without fracture or palpable implant edges.

Case Highlights:

1) Occipital augmentation skull reshaping surgery can be done by custom implant materials like HTR which is also porous.

2) Because HTR is a hard inflexible material it must be placed through a full coronal scalp incision.

3) Fine edging of HTR as an onlay material may need to be supplemented with a bone cement material to create perfectly smooth edge transitions.

Dr. Barry Eppley

Indianapolis, Indiana