Background: Custom skull implants for the flat back of the head are one of the most frequently requested types of augmentative skull reshaping. They are very effective at achieving an improved back of the head shape whether it is for correction of asymmetry or for an enhanced contour. As long as the implant design does not exceed the natural ability of the overlying scalp to stretch, which is usually in the volume ranges up to 150ccs for most people, its placement can provide a satisfactory outcome.

Beyond considering the stretch of the scalp that can accommodate it, a major factor in back of the head skull implants is getting it inserted and properly positioned through the smallest scalp incision possible. This may seem an obvious surgical objective but accomplishing it successfully relies on a combination of novel implant designs and learned surgical technique.

Getting a big skull implant through a much smaller scalp incision fundamentally relies on the principle of material elastic deformation. The shape of the implant must be able to be modified/become smaller so that it can pass through the more narrow incision. The flexibility of solid silicone makes that possible but often that is not even enough. Innovations in the designed shape of the implant can also help with this important intraoperative maneuver.

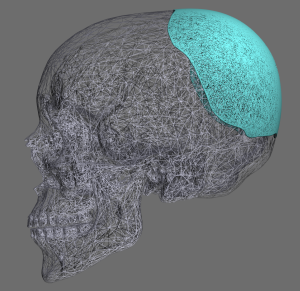

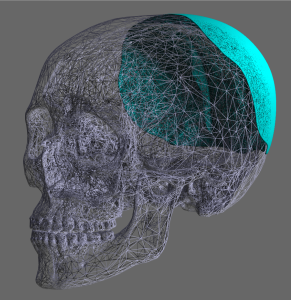

The Saturn custom skull implant concept is that which incorporates a circular internal relief of material. I have previously used internal wedge reliefs which were linear in orientation which had their benefits but never provided optimal working characteristics. The ring of material relief makes the most sense since the implant is circular in shape thus creating implant malleability no matter what position in the pocket in which it lies. The name Saturn of course comes from the appearance of the implant with the ring seen through it.

Case Highlights:

1) A flat back of the head is one of the most common motivations for undergoing a custom skull implant procedure whether it be male or female.

2) In denser female hair the scalp incision on the back of the head is an irregular horizontal design based on the way the hair separates when parted.

3) A more circular skull implant design with a a circular release of material on its underside helps in its insertion and placement. (saturn skull implant)

Dr. Barry Eppley

Indianapolis, Indiana